A 2.0 Volt Variable Power Supply for Phasing Accutrons

This page still under construction, but all the good stuff already here...

|

Why the Omega Watch Co. "Alitest" pictured here? Have you ever suffered from the "Accutron Phasing Blues"? As an introduction to the variable power supply described below, I thought you may be interested in hearing about my own journey learning about phasing Accutrons. In the early 1990's, I obtained this Omega Alitest test set, as Omega service manuals specified it for servicing their f300 and f720 tuning fork watches. It is a very well made (and equally expensive) precision power supply, which continued to be the recommended test set by Omega for all their electronic watches and many generations of quartz Omegas to come. At the time, I was the designated "tuning fork guy" for the local Omega service agent in Perth Australia. Around the mid-90's when mercury batteries were being slowly replaced by silver oxide batteries, many (perhaps most, including me) Accutron repairers were going into panic mode as it became clear that silver oxide cells were problematic in powering Accutrons. Accutrons appeared to be a lot less forgiving than the Omega calibres (some of which were known otherwise as ESA 9162, 9164 and 9210 for other brands) |

| Click to enlarge |

|

Initially, I was forced, as many other repairers were, to mix 'n match coils, tuning forks, index wheels and tweaking finger tensions to try and get a satisfactory result. It was a tedious, time consuming and hit and miss affair to the point I would dread getting an Accutron in for repair. But, as I was working in electronics as well, I spent a some time experimenting with coils and their feedback circuits in the hope I could find a solution in that area. I soon came to realize this was not going to be a practical solution to the problem either. Accutrons were designed to run on 1.35v and that was that, and so when it came to Accutrons I persisted with the Bulova instructions for low-amplitude phasing using my 700 test set (but using the Alitest in the prescribed manner for working on Omega tuning forks ie. phasing at a higher voltage).

I then concluded after some time, aided by my lack of deep understanding of the index mechanism, that dropping the voltage to the coils down from 1.62v to 1.37v was really going to be the only proper way of solving the problem for Accutrons. Knowing that diodes have an intrinsic forward voltage drop, I purchased a big selection of small surface mount diodes to experiment with. I finally settled on a couple of part numbers that gave just the right volt drop. It wasn't overly difficult to find a way of mounting a diode in a coil assembly in such a way as it was hard to see, but it was still quite time consuming to do. From then on, silver oxide cells were no problem, at least in 214's. Well, it was a good try, but not the answer for all Accutrons - quite a few Spaceview owners were understandably not keen on having the visible coil assembly modified.

I still hadn't solved fully the problem of phasing 218's and the other model Accutrons (Omega f300's were only occasionally a problem, usually due to a worn index wheel - see note below**) and I did not like modifying coils anyway. I realized that the difficulty with Accutrons really lay only at the high voltage end of things, so perhaps I should just focus on that end and forget the low volt end and try to phase for the high end, on the idea that the low volt end would take care of itself. It was also becoming clear to me that I didn't understand the index mechanism deeply enough to figure out why f300's were less of a problem. Maybe I'm a bit slow on some things, but it took me a while to really get to grips with understanding the secrets of the index mechanism and how the Accutron design differed subtly from the Omega design. I cannot stress too much that you MUST understand how the index mechanism works in fine detail, and in particular, how important "draw" is to its function. So, I hooked my Alitest variable supply up to my 700 test set, and as they say, the rest is history (for me anyway... this was 1997, perhaps some other repairers in the USA were starting down the same path). What's more, this "High Volt - 3rd run phase" method of phasing worked for all Accutrons and other tuning fork watches as well. So there you go, it wasn't an overnight inspiration, but looking back, it seems I may have been ahead of many others anyway. It was also clear that Omega were already well aware of the limitations of Bulova's approach to phasing for silver oxide cells, and both their Alitest variable power supply and cal. 1250 and 1255 service manuals gave an important clue - if one's eyes were open to see.

If that wasn't enough, it so happened that Bulova themselves already knew well the limitations of their published method of phasing the index mechanism, and also knew what to do to solve it, but chose not to tell. More about this below.

** from experience, this is due to the design of the setting clutch. If the oil dries out and gets a bit gummy, the setting clutch friction increases greatly, and when setting the time, this can cause the index wheel to spin forwards and backwards, shaving the tops of the index wheel teeth off. If you ever need to service one of these watches, pay particular attention to the clutch.

Modifying A Bulova 9920-6604 Variable Power Supply for 0 - 2.0 Volts

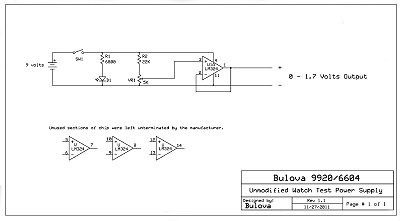

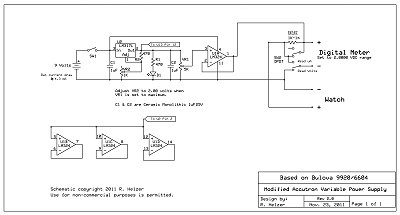

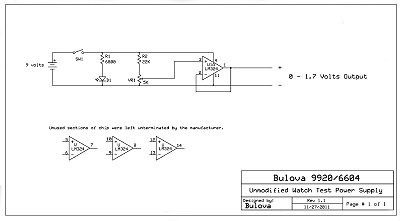

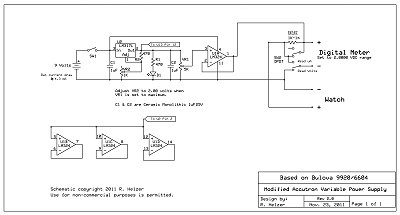

Rich Helzer has designed a nice power supply, based on the Bulova 9920-6604 variable supply. The original unit was variable between about 0v and 1.7v, not suitable for what we want to do, but easily modified (or built from scratch) to be suitable for phasing Accutrons.

|

|

|

| click to enlarge |

click to enlarge |

click to enlarge |

|

|

| The original Bulova variable supply - click to enlarge |

The modified Bulova variable supply - click to enlarge |

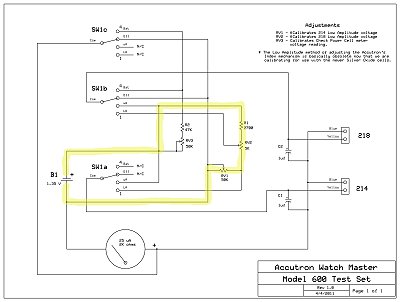

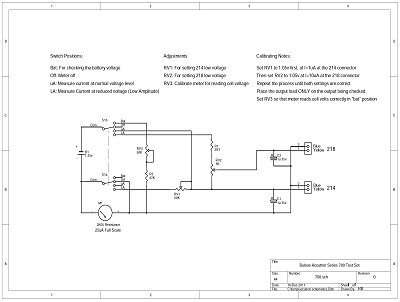

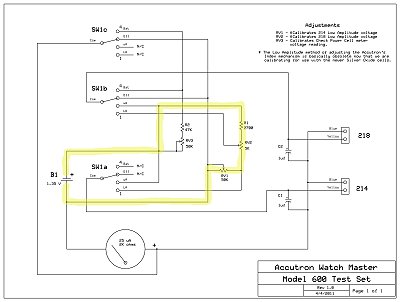

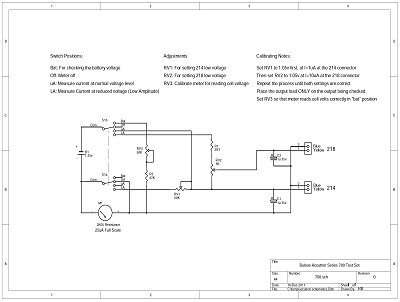

The Bulova 600 and 700 Test Sets

No discussion on power supplies for Accutrons would be complete without mentioning the Accutron test sets. The Bulova Watchmaster test sets were a compromise between their design purpose and Bulova's perceived acceptance of its price by watch repairers, ie price came first, functionality second. Although they are not an ideal design, they were OK for phasing Accutrons while mercury batteries were available. But, since the advent of silver oxide batteries, they are no long suitable for phasing watches, but are still handy to have in between your variable supply and the watch being phased. The analog meter is still superior to read than digital displays, in my personal opinion.

|

|

| The Bulova 600 Test Set Schematic - click to enlarge |

The Bulova 700 Test Set Schematic - click to enlarge |

© Rob Berkavicius September 2011, Bangkok, Thailand and © Rich Helzer September 2011, Texas., U.S.A.

Back