Accutron watches are unique in that they were the first watches to dispense with the traditional "balance wheel and hairspring" as used in mechanical watches and other early battery powered watches. Hence they are of great historical interest, as well as still being a very practical and accurate means of timekeeping to this day. Departing from tradition, they used a tuning fork, not unlike those used by musicians for tuning an instrument. They are inherently more accurate than balance wheel watches for a number of reasons.

The accuracy of a traditional balance wheel watch is dependant on many factors, aside from the design of the balance wheel and escapement. Friction in the pivots of the balance and on the pallets of the escapement due to changes in the quality of the lubricating oil plays a significant role in the ability of a mechanical watch to maintain accuracy and consistency of rate. Also, the condition of the mainspring and the gear train driven by it is very important. The rate of Tuning Fork watches is unaffected, by lubrication, though it is still necesary for the pivots to be lubricated to reduce wear and prevent corrosion. The other major factors affecting accuracy of any mechanical watch are temperature changes and errors due to position (ie. how gravity affects its operation in different orientations).

Tuning fork watches are inherently far less affected by these problems. The fork has no bearings. It is far easier to "build in" temperature compensation into a Tuning Fork than into a circular balance wheel and it's hairspring. The Tuning Fork tines are made of "NiSpan C", which is a special alloy that has virtually no change in elasticty due to temperature variation. Gravity affects Bulova tuning forks in only 2 orientations (tines up and tines down) compared with the usual 5 positions of good quality balance wheel watches. (dial up, dial down, winder up, winder right, winder left). The tuning forks of the ESA movements have virtually zero positional error.

A balance wheel vibrates at usually 2 1/2 times a second, whereas the tuning fork hums at 300-720 times a second, depending on the model. Modern mechanical watches vibrate up to 5 times a second, in an attempt to improve their accuracy by making the balance wheel lower in mass and size, thus reducing their susceptibility to external influences. Technically speaking, the higher the frequency of the oscillating system, the higher is the "Q" (quality) factor, which translated to watches means better timekeeping.,

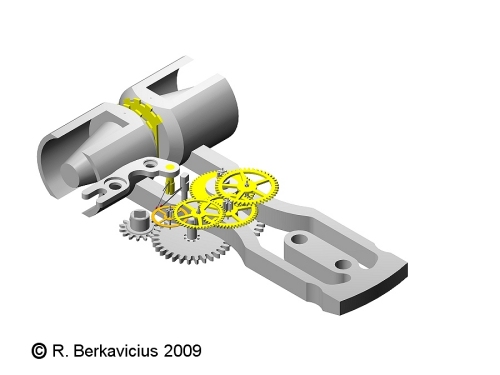

Only Watchmakers of the highest skill can adjust a balance wheel watch for its best possible performance under all conditions. Repairing and adjusting tuning fork watches is considerably easier, as there are no adjustments apart from the index mechanism, which converts the vibrations of the tuning fork into rotary motion. Of course, skill and experience is still needed to adjust the index mechanism correctly.

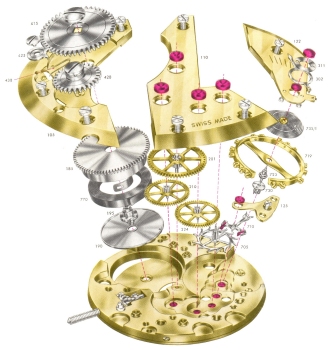

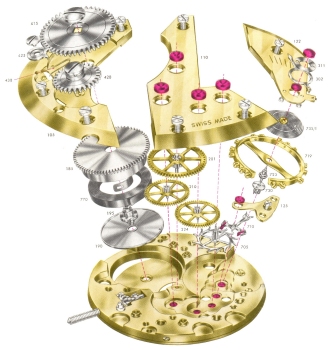

Another interesting difference between Tuning Fork watches and Balance Wheel watches is the flow of mechanical power in the mechanism. A traditional watch has a mainspring which stores the energy to drive the gears. This energy starts off strong at the mainspring and is slowly diminished in torque through the train of gears until it is suitable for use by the balance wheel. How much loss or variation of energy occurs in this process is again a function of the quality of the bearings, the quality of the gear train, and the state of lubrication. The accuracy of the conventional watch is strongly dependant on the constancy of the power which finally arrives at the balance wheel.

In a Tuning Fork watch the power flow is the other way around. The fork drives the gear train, as opposed to a balance which is driven by the gear train. The forces on the gear train of the Tuning Fork watch are far less, and the quality of the bearings and lubrication are of much less consequence to its accuracy than is typical for a balance-wheel watch. Of course, Bulova manufactured the wheels and pinions to the same standard of quality as a conventional watch, which significantly adds to its longevity. Neverthless, they are still susceptible to problems due to dirt and poor lubrication as any precision mechanical item is, and maintenance of an Accutron is often overlooked because of their inherent accuracy and reliabiliy. If maintained correctly, they could be expected to last a long time, as the forces on the bearings are so small.

In summary, we can see that the gear train of a conventional watch performs two functions: it drives the hands and transmits power to the balance wheel. In a tuning fork watch, it only drives the hands.

The tuning fork is kept vibrating by an electronic circuit (Click here for a more detailed description), powered by a battery. While the electronics required to do this are not considered remarkable by today's standards of modern electronics, this is due mostly by a misundertanding of how it works. The tuning fork and electronic circuit combine to form a servo system, which is regulated by signals from the feedback coil and circuitry to keep the fork vibration at the correct amplitude, regardless of external influences. When taken in both the historical perspective and the difficulty of designing an electro-mechanical tuning fork system suitable for a watch, the apparent simplicity of it is a different story.

When the Accutron was first released, not only was it the first watch to be controlled by a transistor, it was one of the first consumer items of any kind to use this device. Up till then, all battery-powered watches had a balance wheel and hairspring which operated a small set of contacts. These mechanical contacts momentarily supplied electrical current to a coil which in turn gave a magnetic impulse to the balance, keeping it moving. The contacts inherently wore out and had to be replaced. They could also be a bit finicky to keep running properly.

The transistor itself was still in its infancy, mostly known by the general public as a Transistor Radio, not the miniature electronic marvel it really is. So it was remarkable not only to use such a device in a watch, but to achieve standards of miniaturisation previously unheard of. Remember in those days, nearly all electronic devices, such as radios and TV's were still based on bulky vacuum tubes.

Back