|

|

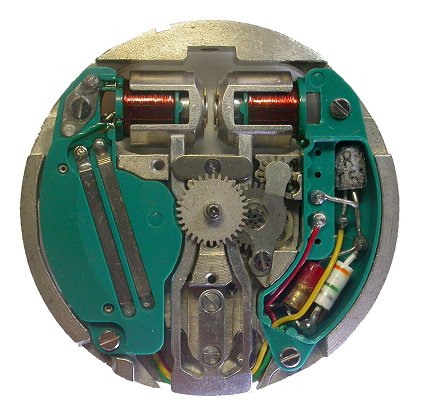

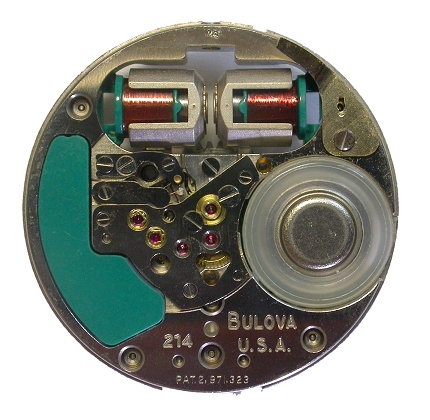

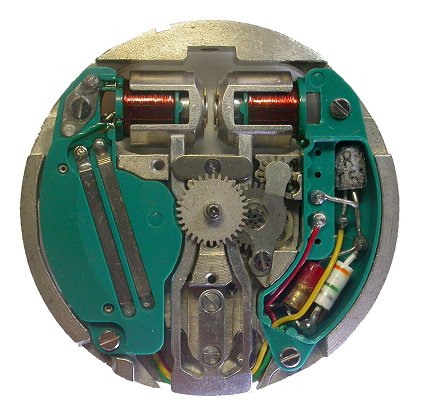

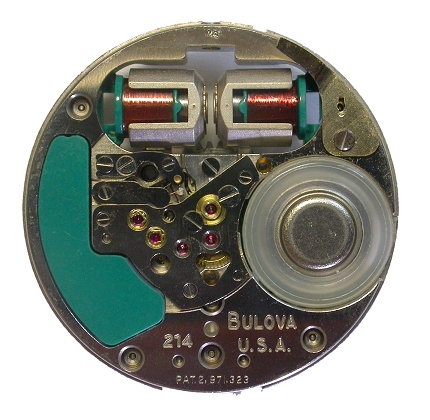

| 214 front (dial side) view | 214 back view |

| Manufacturer: | Bulova Watch Company Inc. |

| Dimensions: | 28.7mm x 5.5mm (o/a) |

| Commencement of Manufacture: | 1960 |

| Tuning Fork Frequency: | 360 Hz |

| Index Wheel: | 300 teeth |

| Derived Calibres | 214H, 214HN, 2141, 2142, 2143 |

This was the first model Accutron. It is probably the most collectable type also. The see-through Accutron Spaceview is no doubt the most well-known and sought-after model of Accutron. Model 214's are easily distinguishable from other Accutrons by the fact that they have no setting crown. The time is set by a small semi-circular ring which swings out from the back of the watch. None of the 214 series were equipped with a calendar mechanism. The construction of the watch would not allow this without major modifications. Calendars were becoming common on watches by the mid 60's, and this was probably a major factor in the development of the 218 calibre. Also, I have heard it said that the lack of space on the back of the 214 for presentation engraving was one of the main reasons for not having a battery hatch on models subsequent to the 214. Aside from that, over the years of manufacture, there were very few changes from the original design. The most significant were the addition of a slipping clutch on the center wheel instead of relying on an accurately-fitted cannon pinion (1960), the addition of stress limiters to the index and pawl fingers (1964), and the addition of a hack spring to some models (not sure when).

An interesting change to the electronics of 214's took place some time in the late 1960's. The original circuit used a Germanium PNP transistor (see Pic 1 below which shows one of the PNP versions), and this was changed to a Silicon NPN type (Pic 2 below). This modification involved a slight change to the construction of both the cell coil and the component coil assemblies, as they needed to reverse the battery polarity for the new type of transistor. The way they did this was quite clever, and they didn't have to make any new parts at all. They also changed the coil specs a bit as well (reduced the number of coil turns), to compensate for the different characteristics of the new NPN transistor. The early PNP type coil pair is easily distinguishable by having three wires connecting the coil assemblies together, whereas the newer NPN type has only two. This change would not have made any functional difference to the watch at all. By the late 60's, most semiconductor manufacturers were decreasing their use of Germanium except for special purpose transistors, so the decision by Bulova engineers to switch to NPN would have been made simply to ensure a continuation of supply of transistors.

214 Schematic Diagrams |

|

| PNP type - click to enlarge | NPN type - click to enlarge |

Note: With spare coil assemblies becoming very difficult to find these days, it has become common practice to make one good set of coils from two dead ones. While this is an excellent idea, care must be taken not to combine coil halves from early and later model coil sets, as their specifications are different.

The 214 Hack SystemThe 214 calibre Accutron is a watch that has the potential accuracy of better than 2 seconds per day, remarkable in its day and still better than most mechanical watches (and many quartz) even in 1998. With this inherent accuracy, it is always seemed strange to me that the second-hand could not be easily synchronized to a time standard. So, at worst, the watch could be up to 30 seconds out when setting it, albeit very consistently.

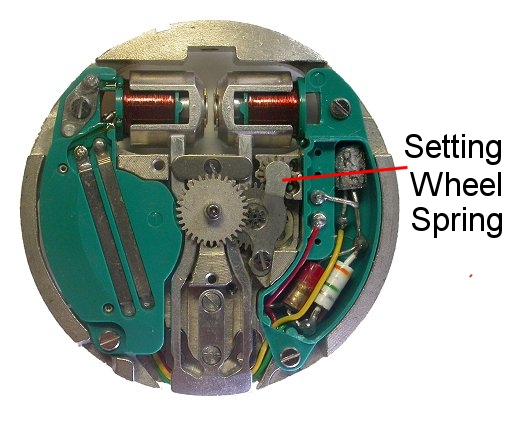

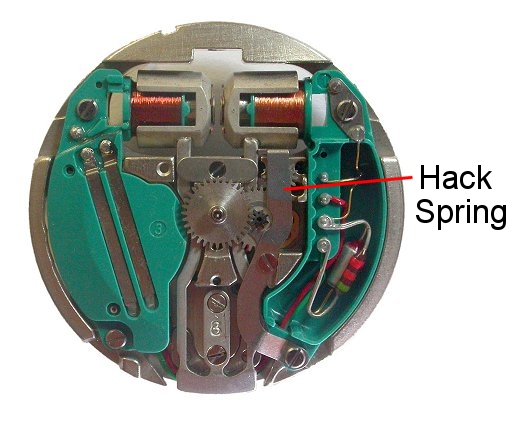

Well, obviously others thought it strange also, so Bulova addressed this problem quite elegantly by a small modification to the setting wheel spring. This spring performs the function of pushing the setting wheel into engagement with the minute wheel when the crown is lifted, allowing the crown to turn the hands (see Pic 1). To achieve a hack feature ( ie being able to stop the second-hand in a desired position), they extended the setting wheel spring at both ends. The lower end was extended down to the lower Component Coil mounting screw, to give the spring lateral stability, and the upper end was lengthened to the tuning fork cup and bent in toward the back of the watch. This little right-angle bend also had a small tapered left-pointing extension. When the crown is lifted, the setting wheel spring (now called the Hack Spring) moves in toward the pillar plate, causing the setting wheel to engage, and at the same time, the little left-pointing extension touches the tuning fork tine, thus stopping the watch immediately (See Pic 2). When the crown is flipped back in, the watch begins running again a second or so later. The original Bulova movemement that incorporated the hack spring from the factory was called the 214H.

Since the hack spring was an afterthought to the original watch design and could be bought as a spare part, it is not uncommon to find watches retrofitted with one. In fact, a hack spring can be fitted to any 214.

|

|

| Standard 214 | 214 with hack spring |

|

|

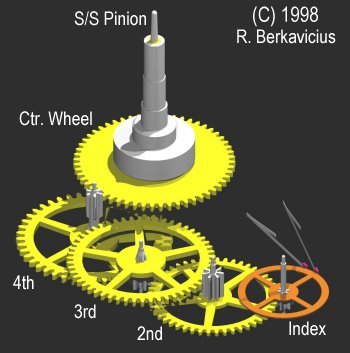

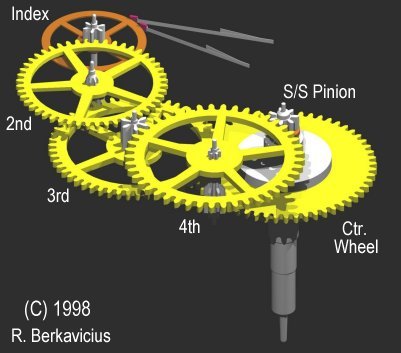

| Pic 3 - 214 Train Top View | Pic 4 - 214 Train Bottom view |

Like myself, many Accutron repairers will have pulled down and rebuilt 214's without giving much thought to the gear train, except for the normal level of inspection required when cleaning and re-assembling. Only when analysed does it become clear that the 214 gear train is a very clever design. Bulova engineers had to get all the right reduction ratios (including one for the sweep second hand) as well as fitting the train into a relatively small (for the size of movement) space. The 4th wheel drives not only the center wheel, but the sweep second wheel as well.

They achieved this by in-effect splitting the gear train at the 4th wheel, in order to get the drive for the sweep second hand. Let's analyze it the same as we did for the 218 and 224. To understand how it works, we need to think of it as two separate gear trains. First, we will consider the train as to how it drives the Center Wheel, (on which the minute hand is mounted), then secondly, as to how it drives the sweep second hand.

| 214 | Center Wheel | 4th Wheel | 3rd Wheel | 2nd Wheel | Index Wheel |

|---|---|---|---|---|---|

| Wheel | 56 | 45 | 54 | 48 | 300 |

| Pinion | -- | 6 | 6 | 7 | 6 |

To get the Center Wheel (on which the minute hand is mounted) to rotate around the dial exactly once per hour, the tuning fork of the 214 has to vibrate 360 times a second for 60 minutes. That is, 360 vibrations x 60secs x 60 minutes, or 1,296,000 times per hour. To see if the gear train will provide the correct reduction to do this exactly, we use the standard watchmaker's method for calculating a gear train. This is to multiply together all the numbers of teeth in the wheels, then multiply together all the numbers of teeth in the pinions, and divide the first number by the second. This gives the total reduction of the gear train. So, using numbers from Table 1:

(56 x 45 x 54 x 48 x 300) divided by (6x 6 x 7 x 6).....and that equals 1,296,000. Yes! the centre wheel will turn once per hour at 360Hz.

Now to see how the second-hand works...

| 214 | Sweep pinion | 4th Wheel | 3rd Wheel | 2nd Wheel | Index Wheel |

|---|---|---|---|---|---|

| Wheel | 7 | -- | 54 | 48 | 300 |

| Pinion | -- | -- | 6 | 7 | 6 |

In the above Table 2, only those wheels and pinions driving the sweep-second pinion are listed. Note that the 4th wheel does not take part in the reduction, it merely serves to transmit the drive from the 3rd pinion to the sweep-second pinion. See Pic 4 above. (That was the real clever bit they worked out). The final reduction to the sweep second pinion is therefore: 3rd Wheel Pinion-to-Sweep Second Pinion. Sorry if that sounds confusing, because it is! Now we will work out the ratios. For the sweep second hand to revolve once per minute, the fork has to vibrate 360 times a second for 60 seconds, or 21,600 vibrations. To see if the gear ratios are correct, we will again apply our boring but useful formula using numbers from Table 2:

(7 x 54 x 48 x 300) divided by (6 x 7 x 6).....and that equals 21,600. The sweep second hand will turn exactly once per minute. Truly a remarkable and cunning bit of work is the 214 gear train!