|

|

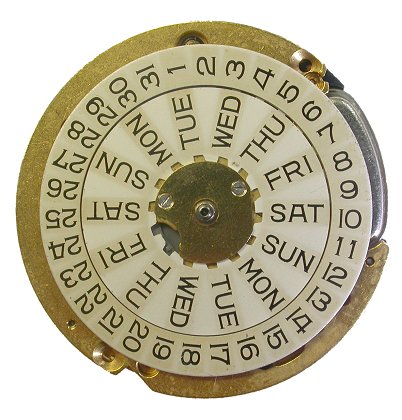

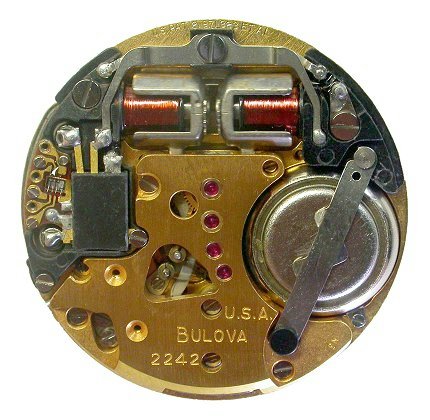

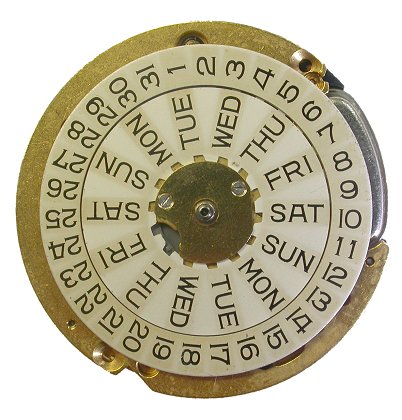

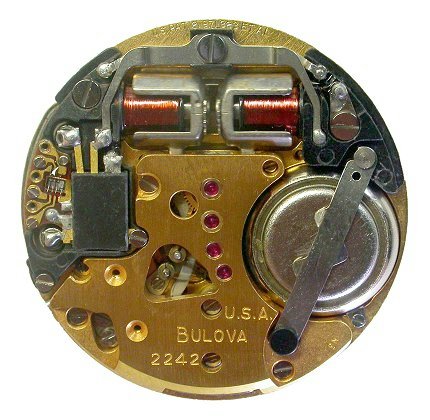

| The Accutron Model 224 (dial side). | Back view of the movement |

| Manufacturer: | Bulova Watch Company Inc. |

| Dimensions: | 29.7mm x 4.9mm |

| Commencement of Manufacture: | 1973 |

| Tuning Fork Frequency: | 341 1/3 Hz |

| Index Wheel: | 320 teeth |

| Derived Calibres | 2240, 2241, 2242 |

This was the last of the Bulova tuning fork watches. Although it is very similar in construction to the 218, it differs markedly in its concept of operation. In previous Accutrons, the accuracy of the watch was dependent on the fork vibrating at exactly the right frequency, which in the 218 is 360 Hz. In the 224 however, the tuning fork is "passive", it just vibrates away, under the control of a quartz crystal oscillator, the accuracy of which sets the rate of the watch. The fork and index mechanism is basically used as a stepper motor. Neverthless, the fork has to be "tuned" anyway, so that it vibrates at as close to the output frequency of the quartz circuit as possible. Slight variations from this theoretical frequency will cause the watch to draw more power from the battery than necessary, but not affect its rate.

The quartz crystal circuit of the 224 oscillates at 32,768 Hz. The 224 tuning fork resonates at 341 1/3 Hz. Sounds like a strange number for a tuning fork at first glance. Why 341 1/3 you ask? Because the 32,768 Hz from the crystal is divided by the electronic circuitry by 96 (div. by 32, then by 3) and that works out to 341 1/3. Very convenient from an electronics point of view. Why a 32,768 Hz crystal you ask? Because 32,768 Hz is equal to 215, which is a number easily handled by digital electronics (and the chip that drives the 224), and thus a frequency readily available from crystal manufacturers. To get special crystals would have incurred a significant lead time (and I imagine cost too).

The rest of the watch may be considered very similar to a normal 218. The only slight differences being on how the index mechanism is "phased" (adjusted), and also that the fork has to be tuned to the quartz oscillator, and a slight change to the train (see below). Bulova supplied a special jig for phasing the index mechanism and adjusting the fork.

One is tempted to ask "why on earth did Bulova consider such an unusual - even bizarre - design for a watch movement?" It wasn't exactly their idea, such a watch design was preceded by the Omega Beta21, and Longines Ultra-quartz. This was a way of achieving the accuracy of a quartz watch without having to re-tool their assembly line too much. They had already almost missed the boat as it was, as Bulova management had virtually ignored all warnings about the new quartz technology, believing it was nothing more than a passing fad. So I think they may have panicked, realizing that they effectively had missed out on a few years of development time, and had to pull a rabbit out of a hat. Thus, the 224 was created. They claimed an accuracy of 3 minutes per year for the 224, which was a 400% improvement over the normal Accutron. The next obvious step was to dispense with the fork altogether, and this was done with the Model 242, which had a miniature electric stepping motor, controlled by a quartz oscillator, driving the gear train. Of course, the indexing mechanism was no longer needed either.

The Accuquartz 224 Electronics

|

| Click to enlarge |

There is not a whole lot to be seen in the circuit above. Most of the electronics are contained within the integrated circuit. We can deduce that the integrated circuit will contain a crystal oscillator drive circuit, a divider of the ratio 215, and an output drive transistor. The rate of the watch is adjusted by adding or subtracting capacitors to the oscillator circuit by means of including or excluding very small screws, each screw location having a specific value of time associated with it. This has the effect of slightly "pulling" the frequency of the crystal to fine-tune it.

And now for some useless but interesting information.....Given that the 224 is essentially the same as a 218, but with different electronics and a tuning fork that vibrates at 341 1/3 Hz instead of 360 Hz, you are no doubt asking the question, as I did, "how did they make the hands turn at the right speed if the fork is vibrating at a slower rate??? Did they reduce the number of teeth on the index wheel to compensate, and if so, how did they account for the 1/3 of a Hz in the fork frequency of 341 1/3 Hz. After all, you can't have a wheel with 1/3 of a tooth on it??!!"

Well, the answer is that Bulova changed the ratio of two gears in the train. And it's amazing that the numbers work out perfectly, not only in the electronics which provides the 341 1/3 Hz frequency, but in the gear train too. We will look at the gear train of both watches, see the differences in the number of teeth, then do some simple calculations to see how they do it.

| 218 | Center Wheel | 4th Wheel | 3rd Wheel (Sweep) | 2nd Wheel | Index Wheel |

|---|---|---|---|---|---|

| Wheel | 60 | 56 | 54 | 45 | 320 |

| Pinion | 10 | 8 | 7 | 6 | 6 |

| 224 | Center Wheel | 4th Wheel | 3rd Wheel (Sweep) | 2nd Wheel | Index Wheel |

|---|---|---|---|---|---|

| Wheel | 60 | 56 | 48 | 48 | 320 |

| Pinion | 10 | 8 | 7 | 6 | 6 |

To get the Center Wheel (on which the minute hand is mounted) to rotate around the dial exactly once per hour, the tuning fork of the 218 has to vibrate 360 times a second for 60 minutes. That is, 360 vibrations x 60secs x 60 minutes, or 1,296,000 times per hour. To see if the gear train will provide the correct reduction to do this exactly, we use the standard watchmaker's method for calculating a gear train. This is to multiply together all the numbers of teeth in the wheels, then multiply together all the numbers of teeth in the pinions, and divide the first number by the second. This gives the total reduction of the gear train. So:

(60 x 56 x 54 x 45 x 320) divided by (8 x 7 x 6 x 6).....and that equals 1,296,000. Magic!

Note: We ignore the centre wheel pinion, as it does not take part in the train reduction up to this point.

Ok, so that works fine for the 218 at 360 Hz, but how does it go for the 224 with a fork vibrating at 341 1/3 Hz? As above, the center wheel still has to do one turn per hour, which in this case is 341 1/3 vibrations x 60 secs x 60 minutes, or 1,228,800 vibrations of the tuning fork. Again, we'll use our formula and this time plug in the numbers of the modified 224 gear train.

So:

(60 x 56 x 48 x 48 x 320) divided by (8 x 7 x 6 x 6) .....and blow me down if that doesn't equal 1,228,800!

As above, we again ignore the centre wheel pinion, as it does not take part in the train reduction up to this point.

So we have just seen that those clever Bulova Engineers only had to change 2 wheels in the gear train to compensate for the different (and seemingly quite strange) fork frequency, and did not have to make a special index wheel for this watch. All the numbers work out theoretically perfectly! Here in Australia, we would say "Bloody Amazing!"

Back