|

|

| Megasonic front (dial side) view. | Megasonic back view. |

| Manufacturer: | Omega Watch Co. |

| Dimensions: | 29.0mm x 5.0mm |

| Commencement of Manufacture: | 1974 |

| Tuning Fork Frequency: | 720 Hz |

| Index Wheel: | 180 teeth |

| Derived Calibres | Cal. 1230 (day/date) |

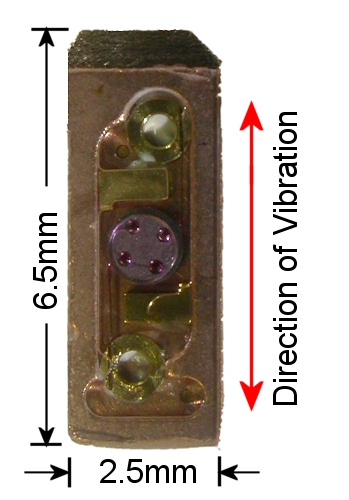

Without any doubt, this calibre is the most unusual Tuning Fork watch ever made. Its principle of operation is quite different (and yet quite similar) to other tuning fork watches. Like the Accutron 214 and the Swissonic watches (ie the ESA 9162 and 9164) this movement was also designed by Max Hetzel, who left Bulova a number of years previously. This design enabled Omega to bypass any patents held by Bulova. Unlike other tuning fork watches, it does not have an index finger attached to the fork and a pawl finger attached to the watch plate. In fact it does not actually even have index and pawl fingers as such, but two "clicks", each of which act as both an index and pawl finger. The index wheel is different also, as it does not have an axle, pinion, or pivots, but runs on 4 balls, sandwiched between 2 ruby discs, mounted in a small hermetically sealed casing called the Micromotor. The Micromotor assembly is mounted on the smaller tine of the tuning fork. It is not serviceable, and requires no adjustment. The Micromotor, at only 0.6 mm thick, stands out as being one of the smallest watch assemblies ever made. I think this would be true even today. See pics below:

|

|

| The cal.1220 Micromotor | The unusual assymetric Tuning Fork |

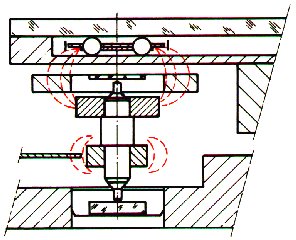

Vibration of the tuning fork causes the index wheel to bounce off two ruby banking springs, and in doing so, each click acts first as an index finger for the other click, then as the wheel moves back, acts as a pawl finger for the other click. So, rotary motion is induced in the wheel.

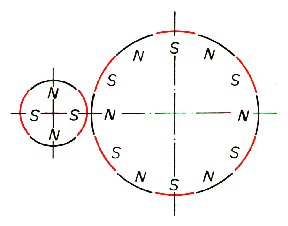

By now you are asking yourself "If the index wheel doesn't have an axle, and is in a sealed container, how does it drive the watch?" This is the other unique feature of the Omega cal. 1220 watch. The index wheel is a disc of polarized magnetic material, magnetically connecting to the coupling wheel below it. Motion is then transmitted by magnetic gears for the first and second reductions of the gear train.

|

|

| Magnetic Coupling of the Index Wheel | Magnetic Gearing |

The assymetrical Tuning Fork is another interesting feature of this watch. Omega says it uses only 75% of the power as would be required to drive a conventional symetrical tuning fork. The electronics are slightly different to what we are familiar with as well. The drive coil is a single winding with no separate feedback coil, and the electronics driving it are contained in an Integrated Circuit, albeit a quite simple one.

The cal. 1220 movement was quoted as having an accuracy of 30 seconds/Month, which is twice as good as other tuning fork watches. This is due to the high frequency at which the fork resonates - 720 Hz.

Warning: It is not recommended you dismantle one of these watches without having the factory service data available. The sequence of disassembly and reassembly is very important. In particular, if any of the magnetic gears come into contact with the tuning fork, they will be instantly destroyed.

|

| Click to enlarge |

Not only did Omega get around Bulova's tuning fork patent with this watch, they also developed an electronic circuit different to all other Tuning Fork watches as well. The Omega 1220 did not use a feedback coil, as can be seen from the circuit. Up until now, all tuning fork watches had a feedback coil. This includes the Bulova 230 series watches, which have a similar looking coil shaped like a flat disk, but which in fact contains a feedback coil.

Despite the uniqueness of this movement, it has two weak points. The first is the fragility of the coil assembly, being quite a large diameter yet quite thin. The second is that despite the fact that the micromotor is sealed, the index wheel can wear out just from bouncing off the banking pins over a long period of time.

Back