| Manufacturer: | Jointly made by Center of Electronic Horology (CEH) Switzerland, Ebauches SA and Omega Watch Company |

| Dimensions: | 30.9mm x 26.5mm |

| Commencement of Manufacture: | 1970 |

| Tuning Fork Frequency: | 256 Hz |

| Index Wheel: | 256 teeth |

| Derived Calibres | Omega Cal 1300, 1301, 1302 |

Although the Accutron 224 was an attempt by Bulova to transition to quartz quickly to save the company from plunging sales due to the quartz revolution, the concept of using a quartz crystal driving a tuning fork/index wheel system had already been done - The Beta 21 had been around for 3 years, and maybe Bulova "borrowed" the idea to speed up development of their own version.

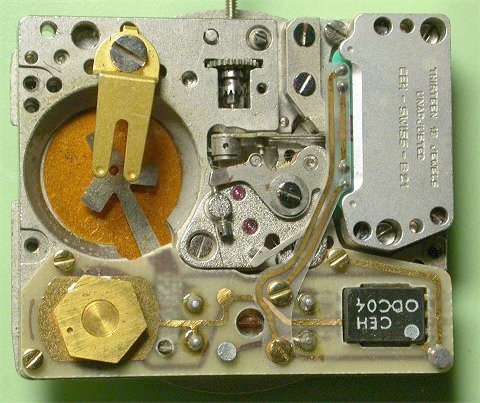

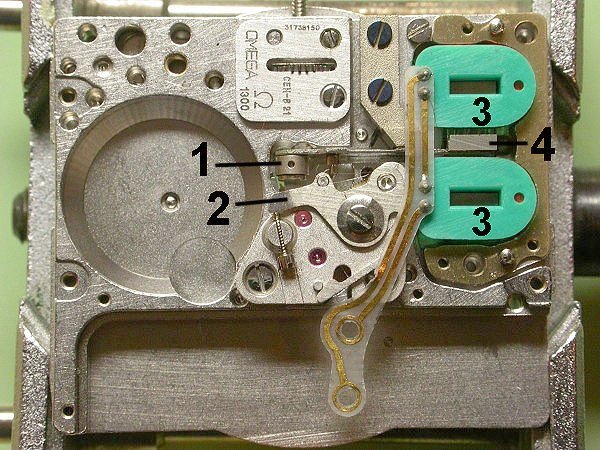

The Swiss R&D group called the Center of Electronic Horology (CEH), Ebauches SA and Omega Watch Company, had in 1970 already developed and produced a watch using the same basic principle that the Accuquartz was subsequently based on. That is, a crystal oscillator running at high frequency divided down to a lower frequency, and then driving a resonator mechanically coupled to an index wheel to produce rotary motion.The movement was called the Beta 21, and in the Omega form, was called the f8192Hz Electroquartz or Calibre 1300. The "f8192Hz" part refers to the frequency of the quartz crystal. Production of this watch lasted only 1 year. Only 11000 cal 1300 watches were made, and only 3000 cal 1301 ,and 1302. A few other manufacturers made watches using the B21 movement, e.g. the Rolex 5100, but only in small numbers. As far as I can see, the only differences between the 1300, and the 1301 and 1302 is a reduced battery height to make the watch slimmer (just by using a thinner battery), and a return of the crown from the 9 o'clock position to the 3 o'clock position. This meant the date wheel had to be re-printed for these models.

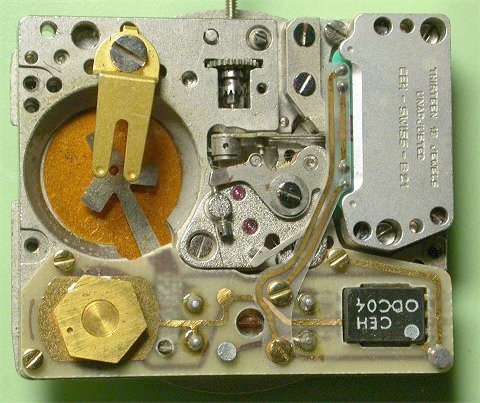

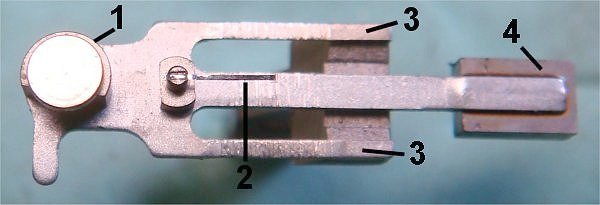

Although this movement is often referred to as a "vibrating reed" type of movement, this is not really the case. It is really a vibrating see-saw, attached to its mount at the neutral or center point of its swing. While strictly speaking it is not a tuning fork, I think it bears enough similarity to be placed in this category. That is, an electronic circuit driving a vibrating element which is mechanically coupled to a gear train by means of an index wheel and index/pawl fingers. Below is a picture of the resonator, with the various parts numbered and explained.

The purpose of the moveable eccentric weight (Item 1) is to slightly adjust the frequency of the resonator. This is achieved by rotating the weight until the movement draws minimum current. At this point, the resonator is vibrating at exactly the same frequency as the drive current from the coils. However, this is not intended to adjust the watch rate, but make the movement more efficient.The rate should be set first before the eccentric is moved .Rate is changed by an adjustable capacitor in the quartz crystal circuit. Exactly the same principle applies to the Bulova Accuquartz 224.

Omega claimed that this movement was accurate to 5 seconds per month. I wear one quite often, and it is usually accurate to 2-3 seconds per month. That is an outstanding level of accuracy, a performance that was only superseded when Omega introduced the cal 1510, in 1974, though its development began about the same as the Beta 21. They had to overcome some big technical difficulties in designing the cal. 1510. It had a specially cut 2.4 Mhz crystal and the gear train was driven by an advanced design stepper motor. Omega guaranteed the Megaquartz 2400 to less than 1 second per month, and it is still regarded by many as the most accurate wristwatch ever made.

Back