|

I use Autocad to do the dial design, as it allows the dial to be drawn in exact 1:1 scale. Also, considerable flexibility is possible in choice of fonts, and also it is very quick to use. A typical dial, as shown, takes me about 10 to 15 minutes to draw. |

|

The image is printed on my 600dpi HP Laserjet printer onto white polyester (or could be mylar) photocopier film. The finished printing quality is excellent and suprisingly enough, looks as good, or perhaps even better, than many professional redials you might see. Although there is a limitation in colour with this method of printing, ie, black printing on a white background, the effect is not unlike that of a porcelain dial. The dials are cut out of the sheet with a sharp pair of scissors and the holes are punched with home-made punches made of brass modeller's tubing. They are attached to the movement with three or four 1/8" square pieces of double-sided tape. |

|

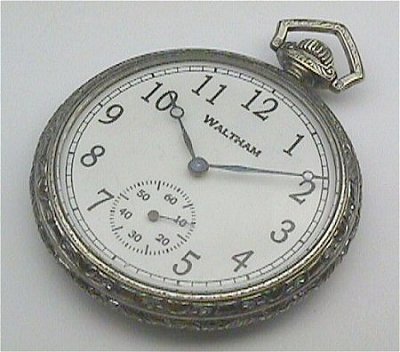

Here is a pic of one of these dials on a 12 size Waltham pocket watch fitted with a Waltham 7j movement manufactured in 1896. It's nice be able to restore a movement and then carry it as a working watch. It may have been decades since this movement was last in "revenue earning" service. |

|

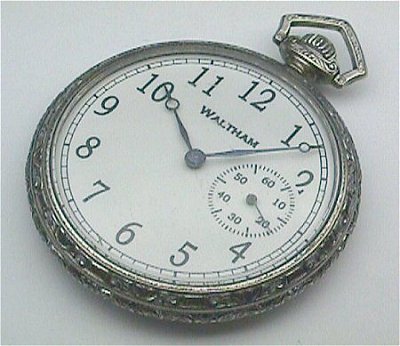

Here is the same case with a 15j Waltham hunter movement manufactured in 1900. This illustrates how my method allows dials to be quickly and easily produced to accomodate differing movements, as it took less than 10 minutes to modify an existing drawing, print it, and cut it out ready for use. |

Text copyright © 2000 by Rob Berkavicius (Rob B)