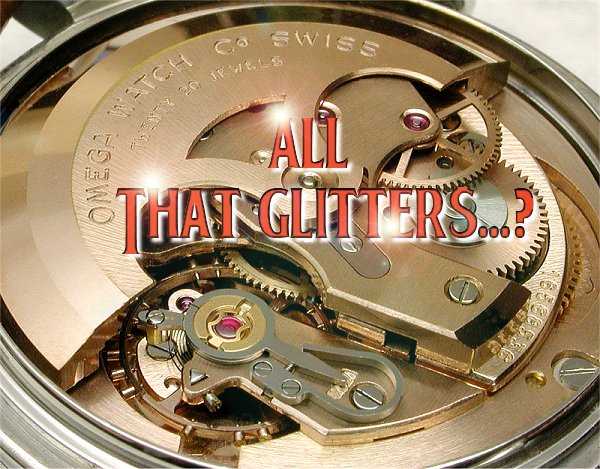

Take a look inside most Omega watches which are more than about 5 years old, and the characteristic beautiful copper colored movement is instantly recognizable as "Omega".

The Omega Watch Company has been plating their movements with this finish since the late 20's (until recently when they switched to rhodium), and this particular style and color of finish makes their movements look very attractive. Traditionally, they use a fine grain machine finished "snail" pattern, or plain straight line graining, with small amounts of highly polished areas, usually anglaged edges, to offset the grain. Add to that the fine matt grey oilstone-dust finish to the steel parts, snailed keyless work wheels, polished screwheads and index, and you have a result that is very attractive and pleasing indeed.

From time to time, one hears this plating referred to as "rose gold" or "pink gold", and in fact the term "rose gold" was actually used by Omega's own email support department in an email to a TZ'ner some time ago. This term has become so accepted that its use has even spread to the websites of some internet watch dealers in describing Omega watches for sale. About twelve months ago, both Paul Delury and myself were taken to task for stating that we believed this plating was not rose gold at all, but most likely either copper, or a beryllium-copper alloy. To support our claim, we used some information, albeit a bit vague, from an Omega technical bulletin which mentioned the plating on some train wheels having been changed. Our critics were not swayed.

Adding to our belief that the plating contains no gold is that it corrodes and discolors readily when exposed to water. One would not expect such a level of corrosion if the plating was rose gold, which by definition, must be an alloy that contains at least 37.5% gold (9ct), the rest being copper to give the desired redness of color, and a percentage of silver and zinc. The picture above shows an Omega f300 movement which suffered the ingress of water into the case. The bottom plate (shown) suffered considerable tarnishing in a short period of time.

Despite evidence to the contrary, the term "rose gold" continues to be used, so I decided the only way to establish the truth is to take a selection of watch parts and have them analyzed by an independant metallurgist.

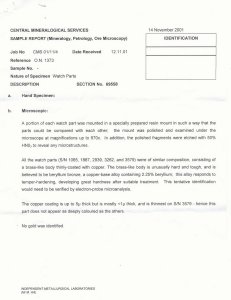

For analysis, five samples of watch plates/bridges were selected, covering a range of production from 1931 to 1975. The parts are from a range of movement models and each is representative of typical Omega parts of their era. All parts were in reasonable condition, with little or no corrosion present, just some handling marks from being stored in parts containers over a period of time.

These samples were handed by Tom Gibbons to Independant Metallurgical Laboratories here in Perth, who then forwarded them to Central Mineralogical Services in Adelaide, Australia, with instructions to analyze the surface plating for gold content, to determine if there were any layers of plating underneath the surface coating, and also look at the base material for overall composition. They were also advised that destruction of the parts was acceptable if necessary to achieve the desired result. The analysis was carried out by HW Fander, who is a highly respected metallurgist both here in Australia and overseas.

A copy of the report can be viewed here by clicking the thumbnails below:

|

|

These tests showed that the plating on the Omega watch parts contained no gold at all, and was in fact pure copper electroplated directly onto the base material. Like any plating, the quality of finish is only as good as the preparation of the base material it is applied to, and obviously Omega went to considerable trouble to get the fine results we are so familiar with. Add to that a little "mystique", which as we know the Swiss watch companies deal out in liberal doses, and a myth is born.

So, like the old saying goes - "All that glitters...", well, now you know the rest of the story!