Text and drawings by Rob Berkavicius, Pics by Paul Delury

Of all the Watch Repairer's tools, screwdrivers are by far the most extensively used, and the simplest to maintain. Yet, their apparent simplicity leads them to be much neglected in the area of tool maintenance.

Little detracts from the look of a watch movement more than chewed and mauled screw heads. However, this form of damage can be easily avoided with a little understanding of screwdriver theory, and with a bit of care and pride in your workmanship. When servicing or repairing a watch, make it your goal to leave the watch in better shape both mechanically and aesthetically than when you received it. To me, this is one of the the hallmarks of a true craftsman and W.I.S (*)

Basically, the purpose of any screwdriver is simply to impart a turning force to a screw. In watches, however, there are special requirements:

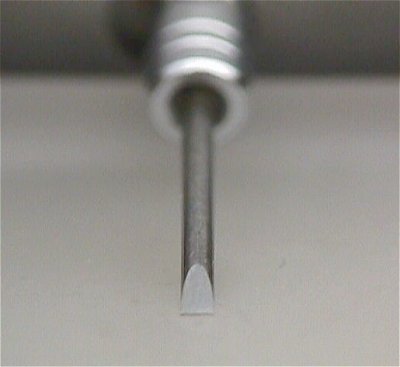

Right and wrong types of screwdriver shapes:

Incorrect types: |

|

|

|

|

| Pic 1 Click to enlarge | Pic 2 Click to enlarge | Pic 3 Click to enlarge | Pic 4 Click to enlarge |

Sharpening a screwdriver:

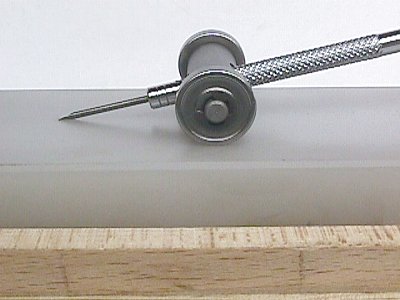

I prefer to use the term "re-grinding", as we are not really sharpening them per se, but re-shaping them. Two tools are required to re-grind screwdrivers: A screwdriver holding jig, (available from any watch materials supplier for a few dollars) and a fine oilstone. 400 grit wet and dry carborundum paper laid flat on a sheet of glass works very well. Choose a stone that does not polish the blade too much, but which leaves very fine grinding marks, as these help prevent slippage, yet cause no damage to the screw.

|

Step 1) Grind the tip of the screwdriver so it is straight and at right angles to the shaft. Use a loupe to view the end of the blade. |

|

Step 2) Fit the screwdriver into the sharpening jig. Place the jigged-up screwdriver on a flat surface. A little observation with a loupe is all that's required to get the angle correct. Look at the blade side-on and end-on with a loupe and align the blade face as flat on the stone as possible. This will greatly reduce the amount of grinding required. Then place on the stone, and work back and forth a few times. Flip the jig over regularly to keep the tip central and the two faces of equal size. Continue until the tip is the correct thickness and the faces are flat. A small amount of sewing machine oil on the stone helps remove ground-off metal and keeps the stone cutting properly. Wipe the stone clean after use. |

The general rule in selecting the correct screwdriver for any particular screw is to choose one with a blade width equal to the diameter of the screw. That way, the torque is distributed across as much slot as possible, minimizing the possibility of burring up the slot and disfiguring it.

|

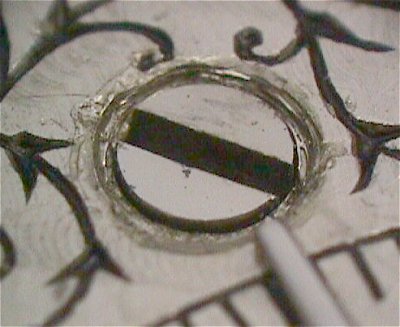

Here is an example where a screwdriver too large in diameter has been used. A corner of the screwdriver has gouged out the plate leaving irreparable damage. |

|

In this example, a screwdriver of too small width was used, leaving the screw head burred up and unsightly. |

There are some screws found in watches which have proportions such that our normal screwdrivers don't fit properly. For example, the screws holding down the ratchet and crown wheels in the keyless works. It is very common to see these screws damaged in watches for this reason. These screws usually have relatively large diameter heads and shallow slots for their given thread sizes. It is a good idea to have some spare screwdrivers set aside and specially ground to handle these large screws, as they are encountered in most watches.

Regular Maintenance

With simple regular maintenance, damage to screw heads can be minimized and damage to watch plates and cocks will not occur due to screwdrivers slipping off screw heads. Every week or two of regular use, examine the tips of your screwdrivers under a strong loupe. Any distortion or chipping will be immediately evident. Often, only a simple touch-up on the oilstone is all that is needed to bring them back to good condition. Such regular inspections and repairs will mean much longer screwdriver life, no damaged screws, and a sense of pride in working to a high standard.

Finally, only use your screwdrivers for the purpose they were intended and they will serve you well!