When someone mentions the name "Omega Speedmaster", the first thing that springs to mind for many of us is "moonwatch", and the associated image of a large stainless steel chronograph with its distinctive white hands and lettering on a black dial, surrounded by a narrow tachymeter bezel. Though the Speedmaster was used in the Apollo moon missions, its career in space began much earlier in 1962, when a Speedmaster was worn by Walter Schirra when he orbited the earth 6 times in the Sigma 7 spacecraft.

The Omega Speedmaster began its long and distinguished history in 1957, when the model CK2915-1 was introduced. This watch was powered by the legendary Lemania cal. 321 movement, a manual wind 3 register chronograph. Since then, Omega has produced more than sixty different models of Speedmaster, utilising a variety of different movements - from the famed cal. 321 to a tuning fork electronic, and yes, even quartz models. Though it is by no means Omega's first quartz watch, the first quartz Speedmaster dates back to 1977, more than 24 years ago. I call this watch the "Almost Forgotten Speedmaster", as it rarely gets mentioned in collector's circles. Perhaps, being quartz, it is somehow considered to be a lesser item than its mechanical brothers. Or, maybe its existence is just simply not well known.

I obtained this example from a watchmaker friend, who had it laying in a junk box. He handed it to me saying "You collect old junk - interested in this?" Say no more! The watch was in poor condition and in need of a total restoration, but how could I refuse - it was in my pocket before he had a chance to change his mind!

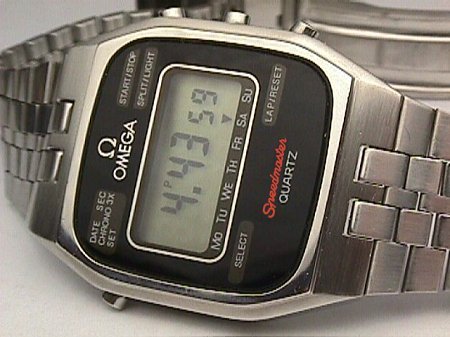

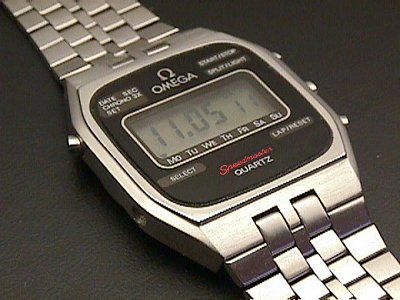

This "7th Generation" Speedmaster (so called because it contains the 7th type of movement used up till then in Speedmasters), was available in 6 different models, based on two case shapes and a number of dial types, gold or stainless steel etc. They were manufactured only for 1 year, in 1977. The movement is an Omega cal. 1620, developed by Omega and SSIH (later to become SMH -see * below). Although it has only basic functions by today's standards, it is neverthless still a very accurate watch, capable of 0.15 seconds per day, or 5 seconds per month. This is better than a lot of quartz watches available even now. The very good accuracy is due to the high quality quartz resonator used, manufactured in-house by SSIH.

SpecificationsThe dimensions of this watch are 33.5mm wide (36.5mm over the pushers), 39.5mm long and only 7.2mm thick. The bracelet is a folded link type, with deployant clasp, and is integrated into the case. The watch weighs a total of 59 grams (2.0 oz) including the bracelet, and being so thin and light is all but unnoticeable during wear.

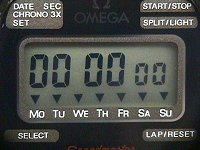

The watch, by means of its single-row LCD display, can display:

|

Time mode 1: Time with seconds, and day indicated by arrow. Display can quickly switched between Mode 1 and 2 (below) by 1 press of the top left pusher. |

|

Time mode 2: Time with no seconds, and day /date displayed. |

|

1/100th second Chronograph. All down-arrows flash when in lap/split mode and the chronograph is still counting. |

|

Normal time and seconds display. The star indicates the chronograph is activated. If the star is flashing, the chronograph function is still counting seconds. |

Today, one might consider the simple dial layout to be "classic" and many watches following this had (and still have) a similar look. As you might expect, the quality of printing on the dial (actually, the printing is on the back of the crystal) is superb. Not obvious from the pics is the Omega name and logo, which are a metallic mirror finish. The word "Speedmaster" is in red, and though this particular variation did not have the word "Professional" on the dial, some of the models in this series did. Why some did and didn't, no-one seems to know as the watches are essentially identical.

The main electronic and functional specifications are:

The Integrated Circuit and Liquid Crystal Display used in the electronic module were manufactured by EM Microelectronic-Marin SA, a subsidiary company of Esa (Ebauches SA), or as we now know them, Eta. The liquid crystal display is still as good as the day it was made, while many contemporary Japanese ones have by now faded to being almost unreadable.

As mentioned previously, this watch was in relatively poor condition when I obtained it. It had been owned by a bricklayer, who obviously took no care of it at all, and it was quite knocked about and caked in concrete. However, despite this, restoration was a relatively easy process, and mainly consisted of refinishing the case, fitting a new crystal and pushers, and refinishing the bracelet. Fortunately, the requisite parts were still available from Omega (the Swatch Group), so that was easy. The 5 new pushers and new crystal cost only around A$100.00 (approx US$52.00). The electronic module was still working fine. It just needed to have the gold-plated battery contacts cleaned of the encrusted battery goo, as the old cells had been left in the watch and had leaked. It was lucky the mess didn't find its way further into the module where it could do some real damage. Here are some before/after pics:

The following pics show some of the steps taken during case refinishing. It was all completely done by hand, using the simplest of home-made tools. Being stainless steel, progress is relatively slow, so patience is required. Even so, it isn't that difficult.

|

Here we are working on the case sides, using wet & dry carborundum paper stuck to a piece of square aluminum tube with double sided tape. Packing pieces are used to set the angle correctly, different ones for each different face. The case is held stationary, and the sanding block is moved. |

|

The right hand side after sanding. I usually use two or three grades of wet & dry, starting with coarse (around 180 or 220 grit depending on how bad the case is). Finish with a grade that emulates the original factory-produced grain. |

|

Working on the curved lugs requires the sanding block to be slightly rotated while moving it lengthwise. Slow and deliberate movements, with not too much pressure, are the only way to keep the alignment right, in order to get a nice even straight-grained pattern. |

|

The top bezel, which is quite small and integral to the case, is repaired by placing a piece of wet & dry paper on a sheet of glass, then carefully grinding the top surface, moving the watch case in a circular pattern. Use finer grades here, as we don't want to remove too much metal. Finish grinding with 1200 grit paper. Since the top surface was originally highly polished, we do the same using metal polish. |

|

The movement module is all cleaned up, and ready for action... |

|

All the new parts have arrived, the case is now refinished, and we have given the stainless steel bracelet the same finishing treatment as the case. All that's left to do is reassemble the watch. First, the new pushers are pressed in, then the crystal is re-fitted (pressed in too) and lastly the movement module is replaced into the case and the back snapped on. Done! The final result looks pleasing. |