Before we start, I would like to say that I believe the the Accutron Index Wheel is the most technically difficult and highest precision watch part ever made, to this day, by any watch manufacturer. They were made on a modified "Micron" hobbing machine, in a way that was a closely guarded secret (which is still known by some). Others tried and failed, and I also believe that Bulova supplied index wheels to Omega for their f300 range of tuning fork watches. They are so delicate that simply touching the edge of one with a metal tool will destroy it. To clean them, Bulova made a small holder that protected them somewhat, but even then, I always clean them in the ultrasonic machine on their own so as not to risk damage. Remember, these are no longer made, and the hobbing machine they were made on was deliberately destroyed by the company which eventually purchased Bulova.

For a detailed description on how to set up or "phase" the index mechanism, click here.

Who better to describe how the index mechanism works than Bulova. If you take the time to analyze the diagrams, it will all become clear. Either that, or you'll be more confused than ever! The following is quoted directly from their 218 Technical Manual (1966)

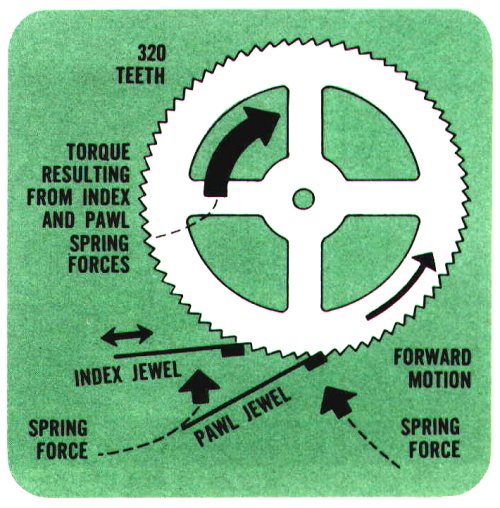

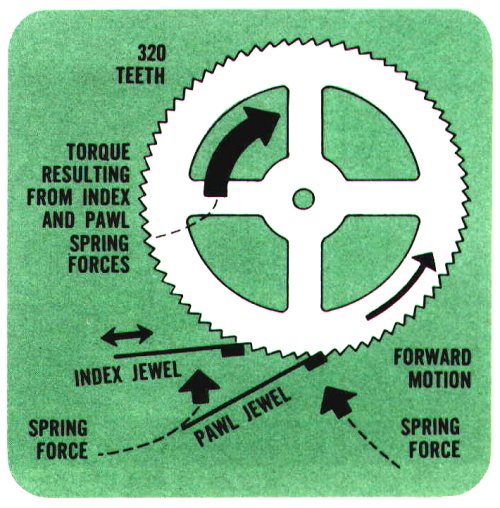

"Fig. 1 is a greatly magnified drawing of the relationship between the index wheel and the two jewels that are in contact with it. Also indicated are the spring forces on the index and pawl jewels, which not only hold them in firm contact with the index wheel, but also exert a torque on the wheel, which is always in a direction opposite to its forward motion. This is because of the geometry of the system and is not unlike the "draw" found in a conventional escapement, which tends to hold the pallet fork against the banking pin. This tendency to "draw" the index wheel back against one of the jewels is very important to the reliable operation of the Accutron indexing mechanism. Each cycle of vibration of the tuning fork causes the index wheel to advance 1 1/2 teeth, then "draw" back 1/2 a tooth for a net advance of exactly one tooth per cycle. Furthermore, the mechanism tolerates a variation in tuning fork amplitude of about +/- 50% before improper indexing occurs. The Following discussion indicates how this is accomplished."

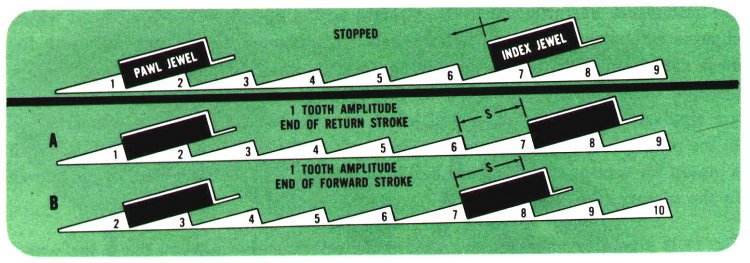

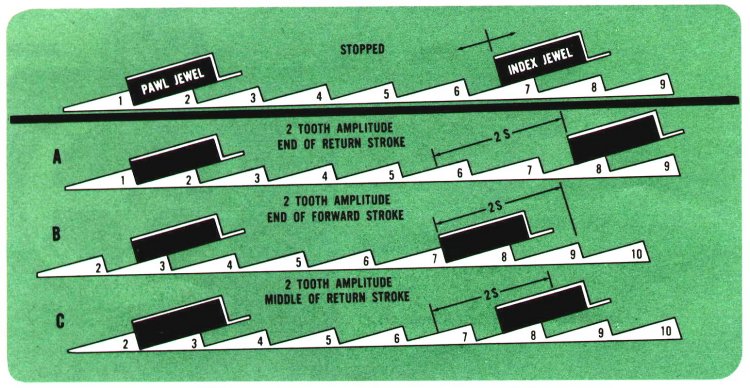

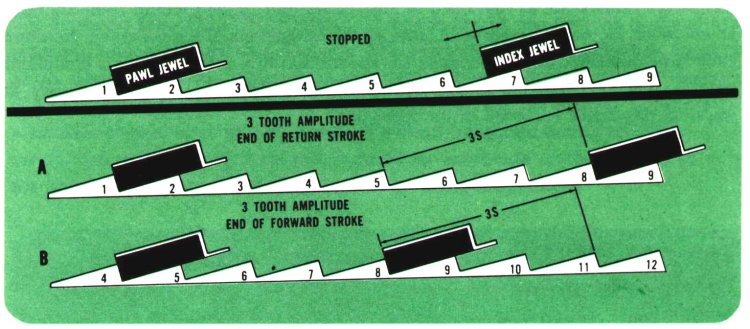

"Figs 2,3 and 4 are diagrammatic representations of the sequence of events in the indexing mechanism, for three widely different amplitudes of vibration of the tuning fork. The mechanism is so constructed and adjusted that when the tuning fork is at rest, with an index wheel tooth engaged by the pawl jewel, (and held there by the "draw" effect described above), the index jewel is located a number of teeth away in a position halfway between two teeth. For simplicity, the amplitude of travel of the index jewel is expressed in terms of tooth length (S). Each figure also shows the idle position as described."

"Fig 2 (A and B) shows a complete cycle of oscillations at an amplitude of one tooth (1/2 tooth right to 1/2 tooth left of the rest position). In moving to the right 1/2 tooth, the index jewel picks up tooth No. 7, and on its return stroke to the left it drives the wheel far enough for the pawl jewel to drop off the end of tooth No. 2, so that the wheel is advanced one tooth. Further oscillations at the one-tooth level of amplitude would advance the wheel exactly one tooth per cycle."

"Fig. 3 (A,B and C) indicate the sequence of events at an amplitude of two teeth (one tooth to the left and one tooth to the right of the rest position). The index jewel, in going one tooth to the right, drops off tooth No. 7, and goes halfway along tooth No. 8. On the forward stroke, however, the first half tooth of travel accomplishes no movement of the index wheel, since the index jewel does not begin to drive the wheel until it strikes tooth No. 7. In Fig. 3 (B), tooth No. 2 has passed beyond the pawl jewel; but after the start of the return stroke the "draw" effect exerts torque on the wheel to bring it back 1/2 tooth to the position shown in Fig. 3(C). Thus, with a two-tooth amplitude of travel of the index jewel, one-tooth rotation of the index wheel results per cycle of oscillation of the tuning fork."

"Fig. 4 (A and B) show the effect of a three-tooth amplitude. The index jewel, in going to the right 1 1/2 teeth, picks up tooth No.8. At the other end of the stroke, it has moved tooth No.8 into the position where tooth No.5 was. The pawl jewel has dropped off the end of tooth No. 4, resulting in a three-tooth advance of the index wheel."

"It can be seen that, for any amplitude from slightly over one tooth to slightly under three teeth, the index wheel advances exactly one tooth for each vibration of the tuning fork. When the total travel of the index jewel reaches three teeth on the index wheel, the wheel advances more than one tooth for each vibration of the tuning fork; in fact, it advances three teeth, and under conditions where the tuning fork reaches such an amplitude, the hands would advance at three times their proper rate."