If you look around the internet, you'll find quite a few Accutron repairers who claim to be able to repair and adjust Accutrons to run satisfactorily on Silver Oxide cells. From reports I have received concerning negative experiences with many repairers, it seems to me that there is a fundamental lack of understanding on how the Accutron index system works, and following on from that, on how to correctly adjust an Accutron to run on silver oxide cells (remember, they were originally developed to be used with mercury cells of a lower voltage. which are now discontinued for environmental reasons). In addition, there are a number of repairers who claim that because of their age, Accutrons can't be expected to work to their original specifications. This is absolutely not true. Any Accutron that has been serviced and adjusted properly, as described here, can be made to work every bit as well as the day it came out of the factory.

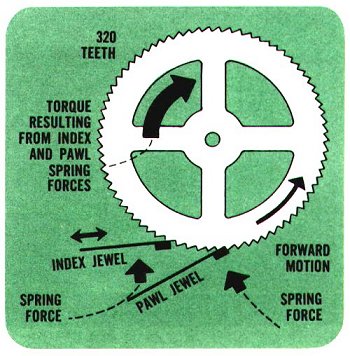

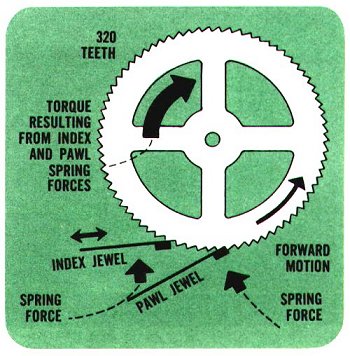

What is "Phasing an Accutron" ?Phasing an Accutron is adjusting the index mechanism so that the index jewel is resting exactly one-half of the distance along one tooth, and the pawl jewel is butting hard against the face of another tooth, when the tuning fork is at rest. As the teeth of the index wheel are so small, this cannot be done accurately enough visually with a microscope, and even if we could, the "dynamic" neutral point of the tuning fork may be slightly different to the static neutral point, Therefore, the adjustment is done with the watch running and by observing the behavior of the index wheel when the watch is supplied with different voltages. When correctly adjusted, the watch will run at the right speed, in perfect synchrony with the vibrations of the tuning fork, with the index wheel clicking forward one tooth for every cycle. A watch so adjusted will be able to withstand the normal knocks and bumps of daily wearing without it gaining bursts of extra time or losses of time which cumulatively would cause it to drift out of the factory specification of +/- 60 seconds per month. Now would be a good time to review exactly how the index mechanism works. Click here. if you aren't entirely clear of the principle of operation. To summarize, here are the most important points to keep in mind for a correctly adjusted index mechanism:

At first glance, the Accutron system seems to be quite straightforward in concept and design. But, like a lot of things. the closer you look at it, the more one appreciates the finer technicalities and sophistication of its design and construction. A lot of engineering went into the development of the Accutron, the Bulova engineers really knew their stuff.The tuning fork resonator and the drive circuit and coils form a "servo system" - in other words, they form a system which senses the state it is in, and has feedback to control that state. In the case of the Accutron system, we have a tuning fork oscillating or vibrating at a certain level of amplitude, with feedback designed to keep that amplitude constant, regardless of external influences. It is important to note here, however, that the feedback control is only relative to the cell voltage. In an Accutron, the purpose of this system is to negate the effects of normal wearing of the watch. Shocks to the watch that may force the tuning fork to vibrate at a higher amplitude cause the feedback circuit to decrease power to the fork and reduce amplitude, and conversely, shocks that force a fall-off in amplitude cause the feedback circuit to increase power to the fork and regain amplitude. Bulova designed the Accutron to run normally, at 1,35v, at about 2 teeth amplitude, which gives the system about 1 tooth amplitude safety margin so that the index wheel does not mis-step.

Now, this is where we run into a bit of trouble. Bulova designed the circuit-tuning fork-index wheel system to run at a nominal voltage of 1.35v, with a designed-in voltage overhead at both the upper and lower voltage range sufficient to allow for amplitude variations larger than the feedback system can cope with. In fact, the absolute amplitude that the fork vibrates at is totally dependant on the battery voltage, with the feedback system only working relative to that voltage. Hence, when we apply 1.55v from a silver oxide cell, we simply increase the nominal amplitude of vibration, with the feedback circuit happily controlling the relative amplitude as before. In doing so, we subtract some safety margin at the high voltage point, and add more safety margin at the low end of the range. The following table lists the voltage range over which the various movements will work. Note that these are design ideals, and may not be exactly realizable in a real-world movement, but they give us a pretty good idea of what to expect.

| 214 | 218 | 230 | 2210 | 224 | |

|---|---|---|---|---|---|

| High Volt Run | 1.75 | 1.70 | 1.80 | 1.70 | 1.75 |

| Low Volt Run | 0.95 | 1.03 | 0.98 | 1.05 | 0.92 |

| Power Cell Volts | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 |

| Max Current (µA) | 7.0 | 10.0 | 10.0 | 5.5 | 11.5 |

And here's the crunch: Bulova's low-amplitude start-stop-start method of phasing the index mechanism for 214's. 218's and 2210's works fine with 1.35v cells because there is plenty of overhead at the high voltage end. But to increase the cell voltage to 1.62v (the fresh voltage of a new silver oxide cell), the start-stop start technique is not accurate enough to take advantage of all the available safety overhead at the high voltage end. So, what to do?

A New Approach to Phasing AccutronsAs can be seen from the table above, Bulova, in designing Accutrons to run on Mercury cells, allowed an overhead of approximately 0.4v above and below the 1.37v maximum cell voltage. This still left about 0.1v at the lower end when the cell had reached the end of its life, which is around 1.05v. These are engineered parameters designed into the watch and cannot be altered. So we have to work within these values and do the best we can. However, it so happens that a large percentage of Accutrons can be made to operate on the higher voltage Silver Oxide cells and still retain enough overhead at the upper voltage range to run acceptably well, still within Bulova specs. So, this leaves us with the possibility of phasing the watch at the high voltage end, and not having to worry at all about the lower voltage end, as a Silver Oxide cell is considered exhausted when it reaches 1.4v - already higher than the maximum voltage of a mercury cell. We achieve this by abandoning the "low amplitude" start-stop-start method of phasing, though we still use it to establish pawl finger tension for some models. Based on that starting point, we then phase the movement at the highest voltage possible, using a 0 - 2.0v variable power supply. This also compensates for any "DC Offset" (or change in the "neutral" position of the fork due to DC current flowing in the coils), which means we can more accurately phase the movement. Rich H. from Texas, friend and fellow Accutron repairer independently arrived at this technique which he has used with success also, and will contribute further by providing schematics for a suitable power supply, designed by himself. This can be found here.

Before we go any further...It would seem on the surface that phasing an Accutron should be a foolproof step-by-step procedure. However, they were manufactured to a certain range of mechanical and electrical tolerances, and after such a time, aging will take its toll on the many variables involved. This is especially true of the tuning fork and electronic circuitry. So, while we can theoretically achieve a certain result, the reality is that this is not always the case. While the majority of watches respond well, there will be some that don't. It takes experience and undertanding to know what is possible for any given watch, when to change out parts, persist with re-phasing or decide an Accucell is the best choice. But, having said that, it is possible to get virtually any Accutron, one way or another, to work to the original factory specs.

Phasing the 214, 218 and 2210The following assumes the watch has been dismantled, cleaned, reassembled and lubricated, and with the index and pawl jewels set exactly as per the Bulova workshop manual for the movement in question. If you are using the Bulova 700 test set in conjunction with your variable power supply, make sure it is set to "Read Microamps". We do not use the "Low Amplitude" setting. Also, I strongly recommend phasing the watch under a microscope, so that the action of the index wheel can be observed clearly. If necessary, make a short stubby screwdriver, this will help to adjust and view simultaneously. Understand that the following adjustments are very critical, and are down at the level of microns. You have to be very exacting on how you perform these steps.

In the 214, 218, and 2210 movements, the pawl bridge performs two tasks: the first is to move the pawl jewel towards the index wheel to attain the correct finger tension, and the second is to move the pawl jewel along the index wheel periphery to adjust phase. For 214's, 218's and 2210's, set the pawl jewel so that it is less than 1/2 jewel away from the index wheel when the pawl bridge is set to its "furthest away" position. For the 214, set the index jewel tension so that it has a 6-7 tooth drop-off when the tuning fork tine is pulled away from the wheel. (refer to manual). For the 218 and 2210, swing the index jewel away from the index wheel and see that the finger gage is set to minimum clearance to the index finger, but not touching (adjust as reqd.), then swing the index finger back into the index wheel until the clearance between the finger and gage is about 1 to 1 1/2 jewel thicknesses. Check the pawl bridge lock screw and make sure it is snugged up enough to provide slight resistance when turning the adjusting cam. Also, double-check the pawl bridge pivot screw to make sure it is tight.

1) Make sure that the index and pawl fingers are set to their correct pre-phase tensions and positions as above. With the movement in its holder, and the power feed clip applied, raise the voltage of the power supply to about 1.05v. Very slowly turn the adjusting cam until the index wheel begins to turn. This places the pawl jewel on the index wheel, but in a random location. This is the "first run phase"

2) Continue to turn the cam very slowly until the index wheel stops. The index jewel tip is then centered near to the root of a tooth relative to the fork's neutral point. Remember, we are running at low amplitude here, a bit over 1 tooth. Because of the "draw" of the pawl jewel pushing the wheel backwards, the result is no forward motion of the index wheel. It just vibrates back and forth. This gives us a known starting point of the index mechanism as a reference to establish pawl finger tension and also locate the phase position.

3) Continue to turn the cam very slowly until the index wheel starts again and begins to run smoothly. We have now reached a point where the index jewel at rest is situated approximately 1/2 way along a tooth, and thus accurately enough in phase for a 1.35v cell. Also, the correct pawl finger tension has been established. This the "second run phase". What is left to do is to take it one step further to achieve the most accurate phase adjustment possible, more accurate than the standard factory recommended procedure can achieve. This will allow us to take maximum advantage of the high volt overhead.

4) At this point, raise the power supply voltage to about 1.75v. See if the index wheel is running normally or fast. If fast, then very slowly adjust the cam a small amount either way to find a spot where the watch again runs at normal speed. Be very careful not to depart too far from the original position found in step 3, or you might end up in another "cycle" of phasing (ie. + or - 1 whole tooth) whereby the pawl finger tension would be wrong.

5) If step 4 went well, then again increase the voltage to, say, 1.80v and repeat the process. Keep increasing the voltage a small amount and keep readjusting until you reach a point where you no longer can stop the wheel double indexing. Then drop the voltage back to the last known level that worked reliably, and re-phase. You get the idea, we are trying to "creep up" to the absolute maximum voltage that we can with the index wheel running normally. If you are able to get the watch to run ok at 1.80 - 1.85v or more, the watch should run fine on a 387S cell.

6) If you can't get the watch to run normally at more than 1.75 - 1.80v, then you have another option: You have so far phased the watch using the run-stop-run technique for finding the "second run phase" and fine tuning it for the highest voltage. Now, you can continue turning the phasing cam past the recommended point and on to the next phasing cycle - the "third run phase". Repeat the process of homing in on the highest voltage as before. This has the effect of slightly increasing the pawl finger tension, and thus increasing the "draw" by a small amount. Often, this is all that is needed to get a satisfactory result.

7) If you still can't get the watch to run normally at more than 1.75 - 1.80v after completing the above steps, and double checking that the train is perfectly free and the fork is not obstructed in any way, then you have only a couple of options: a) changing to another index wheel, coil assembly or fork and re-try, or b) use an Accucell or c) expect that the watch may run ok on the nightstand or display case, and possibly gain a little during wearing.

The following assumes the watch has been dismantled, cleaned, reassembled and lubricated, and with the index and pawl jewels set exactly as per the Bulova workshop manual for the movement in question. If you are using the Bulova 700 test set in conjunction with your variable power supply, make sure it is set to "Read Microamps". We do not use the "Low Amplitude" setting. Also, I strongly recommend phasing the watch under a microscope, so that the action of the index wheel can be observed clearly. If necessary, make a short stubby screwdriver, this will help to adjust and view simultaneously. Understand that the following adjustments are very critical, and are down at the level of microns. You have to be very exacting on how you perform these steps.

The design of the pawl bridges on these movements are different to the movements above. The adjustment screw only moves the pawl finger along the teeth of the index wheel. Finger tension is pre-set by means of the gage pieces on the index and pawl fingers, (same as the 218 or 2210 above) or in the case of the f300, by the gage stored on the oscillator module of each movement, So phasing is simplified in these movements, we don't have to worry about the finger tension during phasing, nor do we have to use the start-stop-start method.

1) Pre-set the pawl bridge to the correct starting position for phasing. ie. for the 219, screw the phasing screw all the way in until it stops, For the 230, adjust the phase screw such that the top edge of the pawl bridge is level with the top edge of the taper on the phase screw. For the f300 and B21, back the phasing screw out until tension is released on the pawl bridge. Then screw the phasing screw back in 1 turn.

2) For the 219 and 230, turn the fingers off the index wheel and set the finger gage starting positions as per the book, then turn the fingers back into the index wheel until the gage-finger clearance is correct. For the f300, use the supplied gage to pre-position both fingers.

3) Set your variable power supply to 1.05v. Very slowly rotate the phase screw anti-clockwise until the index wheel begins to turns continuosly. For the 219 and 230, do not exceed 1 turn of the phase screw, as 1 turn equals about 1 tooth anyway. For the F300, turn the screw clockwise. The movement is now in phase for a 1.35v cells, and now the next step is to set it more accurately.

4) Raise the power supply voltage to about 1.75v. See if the index wheel is running normally or fast. If fast, then very slowly adjust the phase screw a small amount either way to find a spot where the watch again runs at normal speed.

5) If step 4 went well, then again increase the voltage to, say, 1.80v and repeat the process. Keep increasing the voltage a small amount and keep readjusting until you reach a point where you no longer can stop the wheel double indexing. Then drop the voltage back to the last known level that worked reliably, and re-phase. You get the idea, we are trying to "creep up" to the absolute maximum voltage that we can with the index wheel running normally. As per step 5 above, if you are able to get the watch to run ok at 1.80 - 1.85v or more, the watch should run fine on a Silver Oxide cell.

6) If you still can't get the watch to run normally at more than 1.75 - 1.80v after completing the above steps, and double checking that the train is perfectly free and the fork is not obstructed in any way, then you have only a couple of options: a) changing to another index wheel, coil assembly or fork and re-try, or b) use an Accucell or c) expect that the watch may run ok on the nightstand or display case, and possibly gain a little during wearing.

Phasing the Accuquartz is very similar to phasing a 218. The original Bulova instructions called for the use of a special adapter. The purpose of the adapter was to bypass some of the coil current and emulate the "low amplitude" setting of the Accutron meter, as this switch setting doesn't work for a cal. 224. However, since we don't use the low amplitude method for phasing now, we no longer need the adapter.

To phase a cal 224, simply follow the instructions as for phasing a 218. There is one more thing to be done after phasing is completed on a 224. That is, to balance the tuning fork in its "tines up" and "tines down" position. This matches the natural frequency of the tuningfork to the frequency of the circuit driving it, The procedure is exactly the same as in the Bulova 224 service manual, which I will repeat here for your convenience. Note, this has been slighlty edited to suit our new method of phasing, but the principle of adjusting the regulators to balance the fork is the same:

"REGULATOR" ADJUSTMENT

Unlike previous Accutron watches, the Tuning Fork "Regulators" of a Series 224 Accuquartz, do NOT function as "Regulators." The "Regulators" in fact, function as "Balancers." When the "Balancers" are positioned properly, the fork will vibrate in close harmony with the frequency of the Quartz Crystal, and will require a minimum of current.

A. To check Balancers (Regulators), Meter Selector Switch should be in the "Read Microamperes" position.

B. With watch phased and running, hold the watch (in the movement holder) in the tuning fork cups "Up" position. Take careful note of the pointer position. Turn the watch to the tuning fork cups "Down" position and again note the pointer position.

C. If the needle moves more than twice its width, the micro-ampere reading is excessively unequal. The objective is to reduce the higher of the two readings until the difference is no greater than two needle widths, corresponding to 0.2 microamperes. To do this, determine which position produces the higher reading, and lower it. For instance, if the "tuning fork cups up" is higher in reading than "tuning fork cups down," move both "Balancers" towards the center of the movement. If the "tuning fork cups down" reading is the higher reading, then move the "Balancers" towards the outside of the movement. NOTE: It is good practice to divide the amount of adjustment equally between the 2 "Balancers" so that they remain opposite each other at all times.